CNC machining is a manufacturing process where computerized systems control the movement of cutting tools to shape and cut materials with precision. The process starts with creating a digital design or CAD model, which is then converted into machine-readable instructions. These instructions guide the CNC machine in accurately cutting, drilling, milling, or turning the material to create the desired shape.

Flexible MOQ

Flexible MOQ Quick & Precision

Quick & Precision 7*24 Service

7*24 Service

Flexible MOQ

Flexible MOQ Turn Around As Little As 7 Days

Turn Around As Little As 7 Days Reliable And Precision

Reliable And Precision 7*24 Technology Sales On-line Support

7*24 Technology Sales On-line Support

Chemical finishes

Chemical finishes Mechanical finishes

Mechanical finishes Metal plating

Metal plating Bead blasting and sulphuric anodising

Bead blasting and sulphuric anodising Chromate conversion coating and sulphuric anodising

Chromate conversion coating and sulphuric anodising Etching and sulphuric anodising

Etching and sulphuric anodising Powder coating

Powder coating Designing the part using CAD software.

Designing the part using CAD software. Converting the design into machine-readable instructions (G-code).

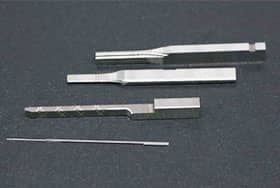

Converting the design into machine-readable instructions (G-code). Setting up the CNC machine, including securing the material and loading the necessary tools.

Setting up the CNC machine, including securing the material and loading the necessary tools. Preparing the CNC program and transferring it to the machine.

Preparing the CNC program and transferring it to the machine. Running the program and monitoring the machining process.

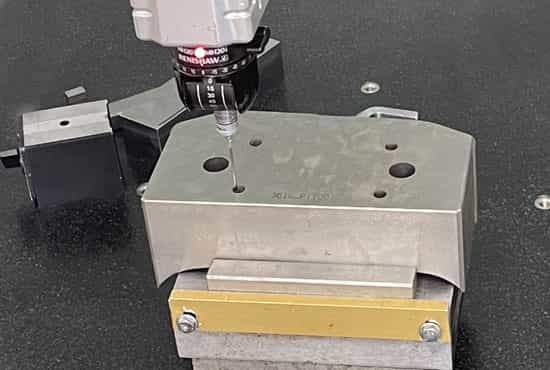

Running the program and monitoring the machining process. Inspecting the finished part for quality and accuracy.

Inspecting the finished part for quality and accuracy.