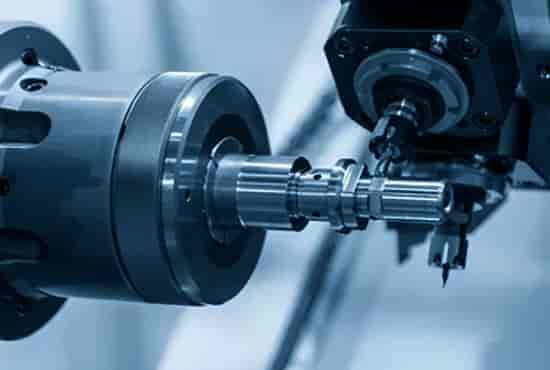

CNC Turning Features

Greater Accuracy

Greater Accuracy

High accuracy and repeatability allows you to reap substantial cost savings, eliminating most human error and ensuring every

finished piece is identical.

Flexibility

Flexibility

CNC turning is highly flexible , and the variety of shapes of cylindrical or conical surfaces can be achieved with CNC turning,

more advanced machines can also bore, thread, knurl, and ream with consistent, precise results.

Can be Used in Various Industries

Can be Used in Various Industries

CNC turning machines are used across a wide array of manufacturing industries, including automotive, medical, electronics

and aerospace.

CNC Turning Service

|

Deliver world-class CNC turned parts to your door as little as 4 days. Our CNC turning service is perfect for prototype and on-demand production.

Flexible MOQ from 1 to 10,000 as per your needs Flexible MOQ from 1 to 10,000 as per your needs

Tight tolerance up to +/- 0.00008 inch (+/-0.002mm) Tight tolerance up to +/- 0.00008 inch (+/-0.002mm)

Turn around as fast as 1 day. Turn around as fast as 1 day.

24/7 technical support 24/7 technical support

|

|

How To Work With Us

|

|

|

|

Step1:Provide Design Drawings

Including 2D+3D Drawings, Materials quantities, and relevant important information.

|

Step2:Production & QC

Transformation from drawing file to part

|

Step3:Received Goods

We deliver world-class milled parts directly to your door.

|

Flexible MOQ from 1 to 10,000 as per your needs

Flexible MOQ from 1 to 10,000 as per your needs Tight tolerance up to +/- 0.00008 inch

Tight tolerance up to +/- 0.00008 inch  Turn around as fast as 1 day.

Turn around as fast as 1 day. 24/7 technical support

24/7 technical support Greater Accuracy

Greater Accuracy Flexibility

Flexibility Can be Used in Various Industries

Can be Used in Various Industries Flexible MOQ from 1 to 10,000 as per your needs

Flexible MOQ from 1 to 10,000 as per your needs  Tight tolerance up to +/- 0.00008 inch (+/-0.002mm)

Tight tolerance up to +/- 0.00008 inch (+/-0.002mm) Turn around as fast as 1 day.

Turn around as fast as 1 day. 24/7 technical support

24/7 technical support

Chemical finishes

Chemical finishes Mechanical finishes

Mechanical finishes Metal plating

Metal plating Bead blasting and sulphuric anodising

Bead blasting and sulphuric anodising Chromate conversion coating and sulphuric anodising

Chromate conversion coating and sulphuric anodising Etching and sulphuric anodising

Etching and sulphuric anodising Powder coating

Powder coating Designing the part using CAD software.

Designing the part using CAD software. Converting the design into machine-readable instructions (G-code).

Converting the design into machine-readable instructions (G-code). Setting up the CNC machine, including securing the material and loading the necessary tools.

Setting up the CNC machine, including securing the material and loading the necessary tools. Preparing the CNC program and transferring it to the machine.

Preparing the CNC program and transferring it to the machine. Running the program and monitoring the machining process.

Running the program and monitoring the machining process. Inspecting the finished part for quality and accuracy.

Inspecting the finished part for quality and accuracy.