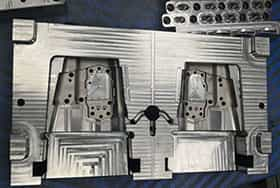

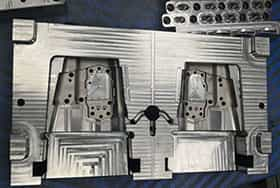

Mould Inserts & Core Machining Features

It is nessary to make an insert for where areas cann't be machined by CNC,EDM or add ventilation.

It is nessary to make an insert for where areas cann't be machined by CNC,EDM or add ventilation.

When there is weak steel, it will be added an insert for changing a new one in the future.

When there is weak steel, it will be added an insert for changing a new one in the future.

It is essential to make an insert for interchanging to get different part shape or changing to get tight torlerance,

It is essential to make an insert for interchanging to get different part shape or changing to get tight torlerance,

It is essential to make an insert for polish where some areas of cavity side or core side are too deep or small.

It is essential to make an insert for polish where some areas of cavity side or core side are too deep or small.

Flexible MOQ Flexible MOQ |

Turn Around As fast As 3 Day Turn Around As fast As 3 Day |

|

Meet Your Perfect Demanding With Any Mold Steels. Meet Your Perfect Demanding With Any Mold Steels.

(Like 1.2343 1.2711 1.2738 H13 420 P20 And More.)

|

Reliable And Precision (minimum tolerance: +/-0.005mm) Reliable And Precision (minimum tolerance: +/-0.005mm)

|

|

|

|

|

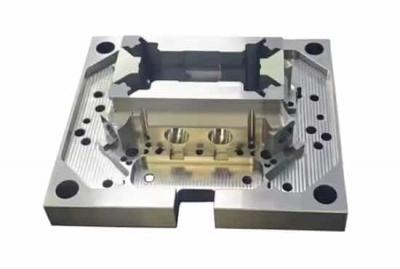

| Core Insert |

Mould Slider |

Precision Injection Mould Insert |

Precision Injection Mould Insert |

| |

|

|

|

|

|

|

|

| Runner inserts |

Slider Inserts |

Slider For Automotive Mould |

Slider For Electronic Product Mould |

| |

|

|

|

|

|

|

|

| Inserts For Automotive Mould |

Inserts For Aumotive Mould |

Inserts For Home Appliance Mould |

Inserts For Home Appliance Mould |

A Part Of Shop Equipments

|

|

|

|

Precision CNC Milling Machine:

Makino V33i 650*450×350mm accuracy:+/-3μ 3pcs

Sodick S50L 500*400*350mm accuracy:+/-3μ 3pcs

|

High Speed CNC Machine:

YASDA YMC430 420*300*250mm accuracy:+/-3μ 1pcs

roders RXP400 410*294*210 mm accuracy:+/-3μ 1 pcs

|

Wire Cutting Machine:

SodicK AG400LS 400*280 *250mm accuracy:+/-3μ 2pcs

SodicK ALN400G 600 *400*350mm accuracy:+/-3μ 1pcs

|

| |

|

|

|

|

|

|

Discharge Spark Machine:

Sodick AD30LS 320*250*250mm accuracy:+/-3μ 2pcs

Makino EDAF2 350*250*250mm accuracy:+/-3μ 2 pcs

|

CNC Turning Machine:

Taiwan Taikan LP36M accuracy:1.5μ 5pcs

|

|

How To Work With Us

|

|

|

|

Step1:Provide Design Drawings

Including 2D+3D Drawings, Materials quantities, and relevant important information

|

Step2:Production & QC

Transformation from drawing file to part

|

Step3:Received Goods

We deliver high-quality parts directly to you.

|

No Minimum MOQ

No Minimum MOQ In-house Production

In-house Production Quick & Precision

Quick & Precision 7*24*365 Service

7*24*365 Service It is nessary to make an insert for where areas cann't be machined by CNC,EDM or add ventilation.

It is nessary to make an insert for where areas cann't be machined by CNC,EDM or add ventilation. When there is weak steel, it will be added an insert for changing a new one in the future.

When there is weak steel, it will be added an insert for changing a new one in the future. It is essential to make an insert for interchanging to get different part shape or changing to get tight torlerance,

It is essential to make an insert for interchanging to get different part shape or changing to get tight torlerance, It is essential to make an insert for polish where some areas of cavity side or core side are too deep or small.

It is essential to make an insert for polish where some areas of cavity side or core side are too deep or small. Flexible MOQ

Flexible MOQ Turn Around As fast As 3 Day

Turn Around As fast As 3 Day Meet Your Perfect Demanding With Any Mold Steels.

Meet Your Perfect Demanding With Any Mold Steels.  Reliable And Precision (minimum tolerance: +/-0.005mm)

Reliable And Precision (minimum tolerance: +/-0.005mm)

Chemical finishes

Chemical finishes Mechanical finishes

Mechanical finishes Metal plating

Metal plating Bead blasting and sulphuric anodising

Bead blasting and sulphuric anodising Chromate conversion coating and sulphuric anodising

Chromate conversion coating and sulphuric anodising Etching and sulphuric anodising

Etching and sulphuric anodising Powder coating

Powder coating Designing the part using CAD software.

Designing the part using CAD software. Converting the design into machine-readable instructions (G-code).

Converting the design into machine-readable instructions (G-code). Setting up the CNC machine, including securing the material and loading the necessary tools.

Setting up the CNC machine, including securing the material and loading the necessary tools. Preparing the CNC program and transferring it to the machine.

Preparing the CNC program and transferring it to the machine. Running the program and monitoring the machining process.

Running the program and monitoring the machining process. Inspecting the finished part for quality and accuracy.

Inspecting the finished part for quality and accuracy.